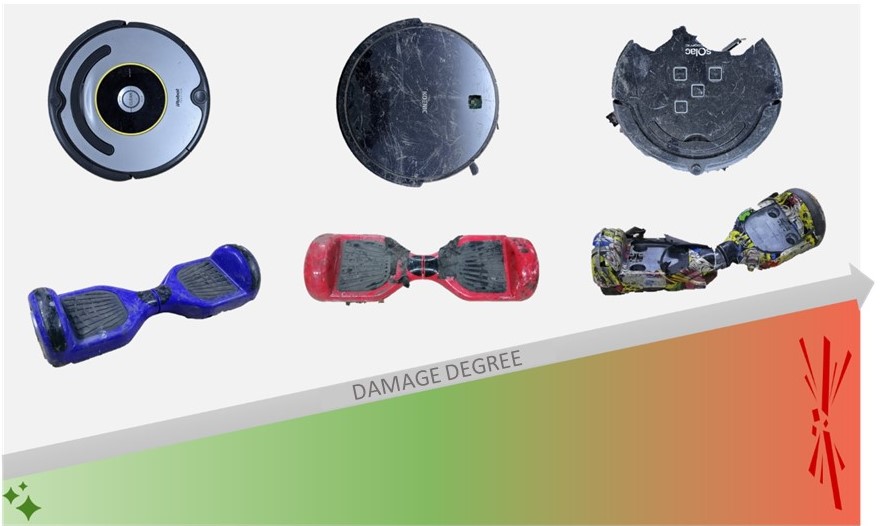

Recognizing the different devices, regardless of their condition upon arrival at the recycling plant, is a significant challenge for the REEPRODUCE project, which aims to implement emerging electronic waste identification systems.

Emerging electrical and electronic devices, such as autonomous vacuum cleaners or hoverboard-type scooters, still face many of the issues encountered by traditional equipment at the end of their useful life. The wide variety of models and brands, each with unique designs, highlights a lack of ‘design for recycling’. To this difficulty must be added the different degree of deterioration that WEEE presents when it arrives at the recycling plant. Therefore, the databases that feed the identification and dismantling systems must contain information not only on the different models and designs of equipment that could reach the recycling plant, but also on the different degrees of deterioration that they could present. These systems must be able to recognize and classify equipment regardless of its status. In this sense, it is vitally important to enrich the database with equipment in different degrees of deterioration. This should include examples of equipment in factory condition, as well as those with minor damage such as scratches or dings, and even equipment with a high degree of deformation.

These emerging residues are a source of rare earths since they contain permanent magnets that are necessary for their operation. Rare earths are classified as critical raw materials by the European Commission. The European REEPRODUCE project aims to recover these raw materials, especially neodymium (Nd) from WEEE generated in the EU.

It is evident that there is a lack of widespread ecodesign strategies among manufacturers when it comes to considering the end-of-life of these new types of electronic equipment. These products are being manufactured at a time when the importance of incorporating elements that facilitate recycling is widely known. However, it is equally crucial to enhance the logistics chain for end-of-life management, encompassing the collection, transportation, and storage of these devices. This improvement in the overall treatment of equipment would greatly facilitate the efficient recovery of valuable materials. In essence, it is imperative to acknowledge WEEE for what they truly are: items with a very high added value.

A consortium of 15 partners from large, small and medium-sized companies and from research and technology organizations spanning the entire European rare earth value chain participates in the development of REEPRODUCE, under the coordination of the Norwegian Technology Center SINTEF.

Este proyecto ha recibido financiación del programa de investigación e innovación Horizon Europe de la Unión Europea bajo el acuerdo de subvenciones No 101057733

Financiado por la Unión Europea. Sin embargo, los puntos de vista y las opiniones expresadas pertenecen únicamente a los autores y no reflejan necesariamente las de la Unión Europea o la Agencia Ejecutiva Europea de Salud y Digital. Ni la Unión Europea ni la autoridad otorgante pueden ser considerados responsables de ellos.